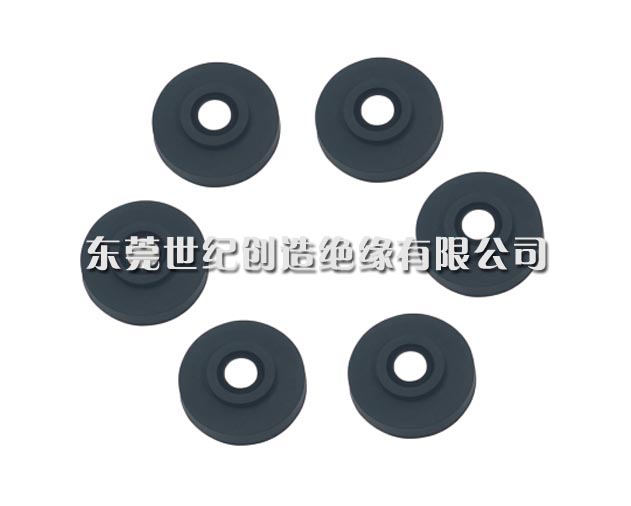

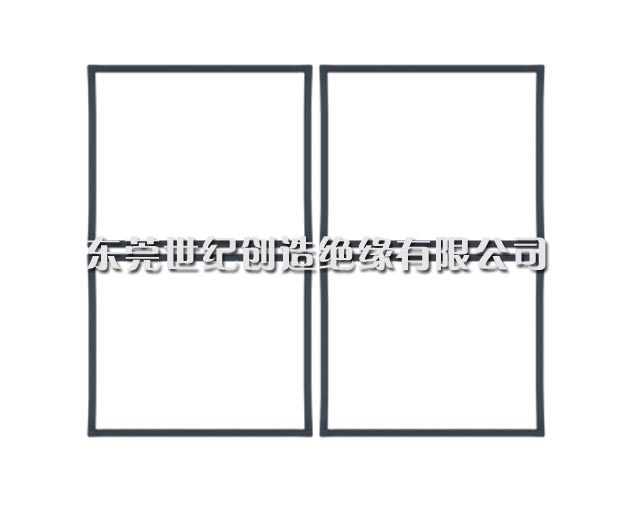

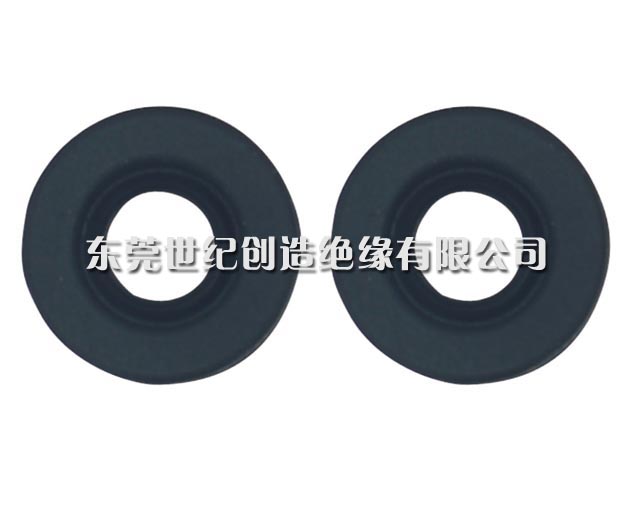

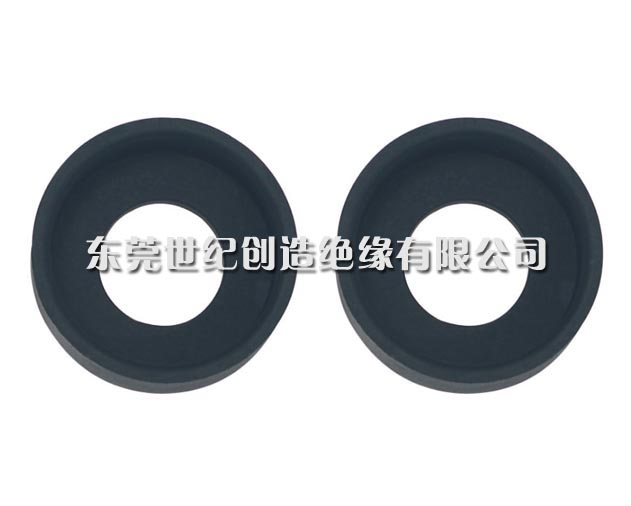

NBR Series

Classification:

- Click count:1027

- Online inquiry

Features of NBR materials: Extremely good resistance against gasoline and aliphatic hydrocarbon oils (next only to polysulfide rubber, acrylic ester and fluororubber and better than all the other rubbers), good heat resistance, air tightness, and resistance against abrasion and water, and strong cohesive force. Defects of such material are the poor resistance against coldness and ozone, poor strength and elasticity, poor acid resistance, poor electrical insulating property, and poor polar solvent resistance.

Service temperature: Approximately -30℃?+100℃.

Main applications: Widely used to make oil-resistant rubber products, oil-resistant gaskets, spacers, casing pipes, soft packages, flexible rubber hoses, printing and dying rollers, and cable gum materials. It is also essential elastic materials in the automotive, aviation, oil and printing industries.

Related products:

Related news:

- Introduction to Rubber Sponge

- The main factors affecting the vulcanization process of rubber

- The principle of rubber foaming and how it is used for listening to voice during mixing in an internal mixer

- How to distinguish the quality of rubber foam strips?

- How rubber foam strips have a shock-absorbing effect

- Selection of Rubber Raw Materials for Rubber Sponge Products

- Why do we need to undergo secondary rubber vulcanization?

- What are the high-temperature resistance characteristics of rubber sponge materials reflected in?

- Common processing methods for sponge rubber foaming

- Why does rubber undergo significant changes in its properties after vulcanization